|

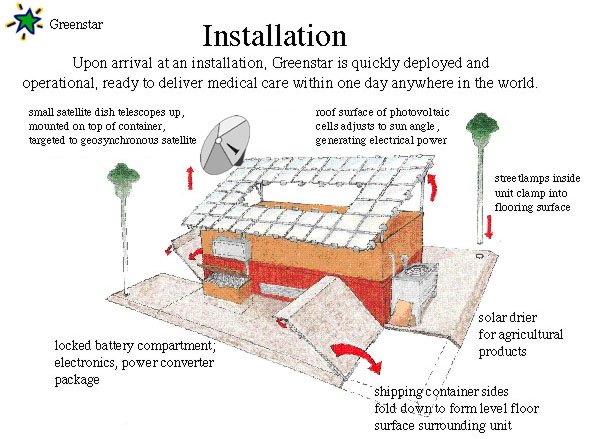

First, the sides of shipping container are un-hooked at the corners; they fold down to form a continuous floor surface that surrounds the unit. Next, the roof of Greenstar, which contains a large array of solar cells, is lifted up to the correct angle to receive the sun's rays. It is plugged into an inverter, which transforms the DC power generated by the cells into usable AC power, and into a battery array, which stores electrical power for times when the solar array is not active. All this equipment is shipped secure within Greenstar. Now the satellite dish is telescoped up from within the unit, aligned to the appropriate geosynchronous satellite, and tested with its conrtroller and router inside the unit. A local-area network (LAN) of up to 50 computers may be supported by a single dish. Next, auxiliary Greenstar features like the water purifier and solar drier are mounted outside the unit, and four streetlamps are clamped into the four corners of the floor surface. Finally, the computers inside the unit, which are pre-wired into a local area network, are connected to the satellite, and set up for connection to the Internet. Two-way video for the vital telemedicine functions is tested, and the Web server is configured to host a unique domain name for each Greenstar unit, allowing it to host a website that the local people can be trained to operate. The basic installation process can be completed within a single working day, assuming that the shallow earth foundation has been prepared in advance of arrival. |

When Greenstar is loaded off its

delivery truck, it can be quickly secured in a shallow earth

foundation that two people can dig in a day; no concrete or masonry

is required, since Greenstar is a tough structure in itself.

When Greenstar is loaded off its

delivery truck, it can be quickly secured in a shallow earth

foundation that two people can dig in a day; no concrete or masonry

is required, since Greenstar is a tough structure in itself.